The arrival of Google’s first Chromebook assembly line in Haripur is a landmark achievement. But the real test isn’t assembling half a million units—it’s whether this project can build the domestic supply chain that true manufacturing requires.

Introduction: Beyond the Headline

In a significant move for Pakistan’s tech landscape, Google has officially launched its first Chromebook assembly line in the country. This venture, a collaboration between the tech giant, the Ministry of IT and Telecommunication, and local partners Tech Valley and the National Radio & Telecommunication Corp (NRTC), is more than a single factory opening.

The project, based in Haripur, targets an initial production of 500,000 to 600,000 units annually and has already created over 600 direct jobs. Government officials have hailed it as a pivotal step toward the “Digital Pakistan” vision, promising to boost digital literacy, create high-skilled jobs, and position the country as a regional tech hub.

But beneath the celebratory announcements lies a more complex question. Is this a self-contained achievement, or can it act as the catalyst for something far greater: a thriving domestic ecosystem for manufacturing electronic components?

Section 1: Deconstructing the “Made in Pakistan” Chromebook

A New Model of Partnership

This isn’t just a foreign company setting up a factory. The Chromebook project is a textbook example of a public-private partnership. The government, through figures like Minister of State for IT Shaza Fatima Khawaja, has actively facilitated the environment, while local firm Tech Valley acts as the operational partner and “country partner” for Google’s developer initiatives. This collaborative model is itself a breakthrough, signaling to other global tech firms that Pakistan is open for business.

The Immediate Impact

The tangible benefits are already materializing. The creation of over 600 jobs, with a noted focus on employing young engineers and women, is a direct economic injection. Furthermore, the goal of producing up to 600,000 devices locally aims to make technology more affordable and accessible for the crucial education sector, a stated priority for partners like Tech Valley.

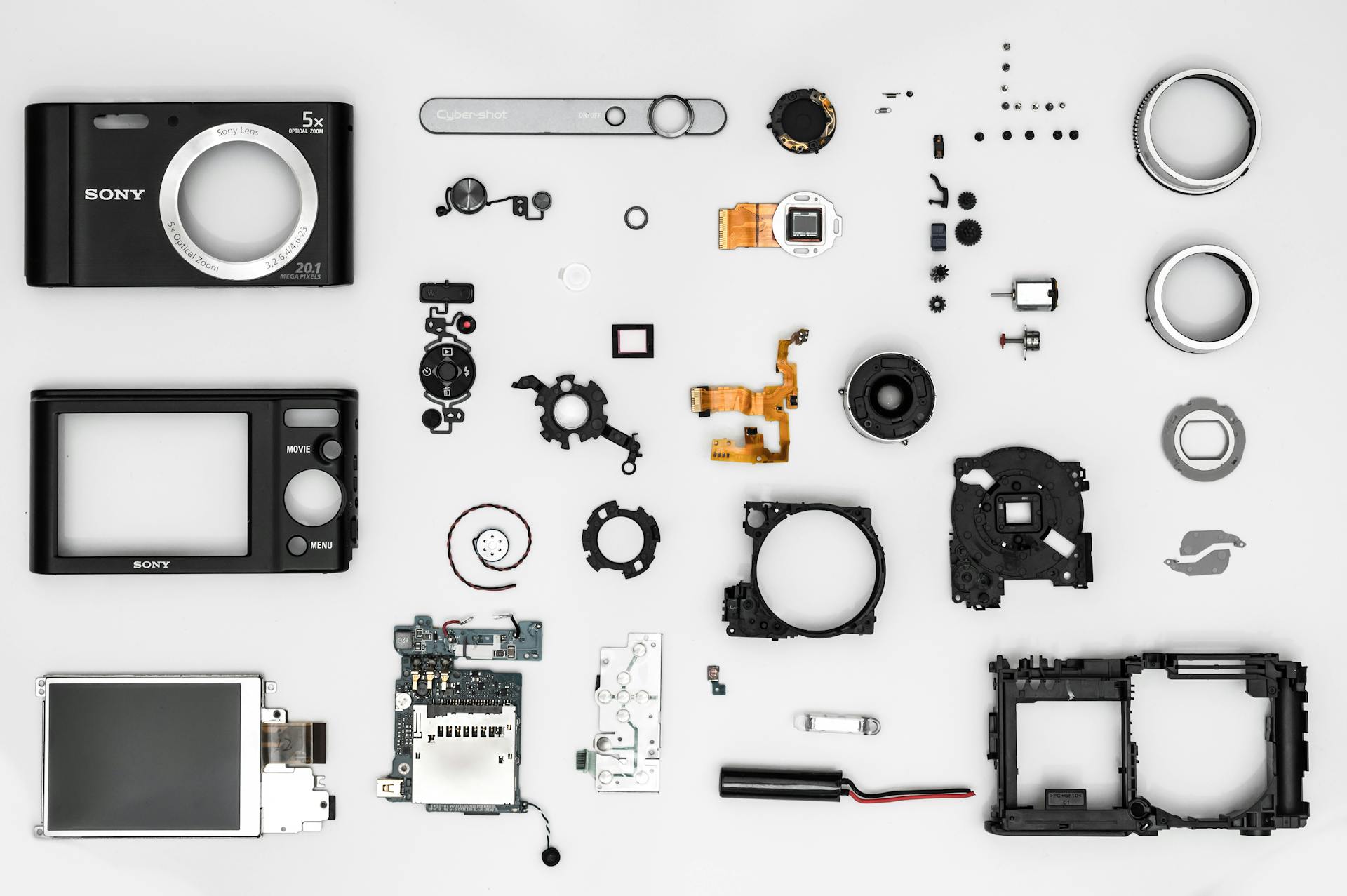

The “Assembly” Reality

It is crucial, however, to understand what “local production” currently means. Like the smartphone industry—where Pakistan now assembles 94% of its phones—the initial Chromebook production will rely on imported components in Completely Knocked Down (CKD) or Semi-Knocked Down (SKD) kits. The screens, chips, motherboards, and other core parts are shipped in and assembled here. This is the essential, but elementary, first step on the manufacturing value chain.

Section 2: The Crucial Leap – From Assembly to Ecosystem

The Expert’s Warning

The risk of stalling at this assembly stage is real. Economist Ammar Habib Khan provides a crucial framework for understanding this. He argues that the benefits of local assembly are limited if the goal is merely import substitution—replacing finished imports with locally assembled ones. Without a clear strategy for export promotion, this model can inadvertently “destroy consumer surplus” by maintaining high prices and fails to build long-term international competitiveness. The value lies in creating an export footprint.

What a “Component Ecosystem” Actually Looks Like

For the Chromebook plant to be transformative, it needs to spark demand for local components. This doesn’t happen overnight but through a phased approach:

-

Phase 1 (Low-Tech Start): The most immediate opportunities lie in localizing the production of plastic casings, device packaging, user manuals, and simple cables. These are low-hanging fruit that can immediately reduce import dependence and create ancillary industries.

-

Phase 2 (Medium-Tech Goals): The next step could involve the assembly of battery packs, keyboards, and speaker units. This requires more technical investment but is a natural progression.

-

Phase 3 (Long-Term Vision): The ultimate goal is to attract investment for more complex sub-assemblies, potentially even attracting PCB (printed circuit board) manufacturing plants.

The Smartphone Precedent

The mobile phone industry offers a clear precedent. Despite assembling nearly all phones sold domestically, Pakistan has struggled to develop a significant local component industry. The Chromebook project now poses the question: can we learn from this and design a strategy that pushes beyond mere assembly from day one?

Section 3: The Stakes – What Success or Failure Looks Like

The path taken from here will determine whether this project is a footnote or a foundation.

The High-Road Scenario (Success)

In this future, the Chromebook plant acts as a magnet. The consistent demand for half a million units annually gives investors the confidence to set up local factories for the components mentioned above. The government, learning from the smartphone experience, introduces smart incentives and Phased Manufacturing Programs (PMPs) that gradually increase local content requirements. This creates thousands more jobs, significantly reduces the import bill, and positions Pakistan as a credible exporter of not just assembled devices, but also components.

The Low-Road Scenario (Stagnation)

The alternative is a project that plateaus. The assembly line operates efficiently but remains entirely dependent on imported kits. The lack of a clear export strategy means the units are only for the domestic market, limiting scale and competitive pressure. The potential for a component ecosystem remains untapped, and the broader economic benefits fail to materialize.

Conclusion: The Path Forward – Igniting the Spark

The Google Chromebook plant provides the potential energy for a manufacturing renaissance. It is a resounding vote of confidence in Pakistan’s potential. But potential energy alone does not power an economy.

To convert this spark into a self-sustaining fire, a conscious, coordinated effort is required:

-

Strategic Policy: The government must move beyond celebrating assembly and craft policies that actively encourage local value addition. This means tax incentives for component manufacturers and a clear, predictable roadmap for increasing local content.

-

Industry Initiative: Local partners must proactively identify and develop local suppliers, even for the simplest components, building resilience and cost-effectiveness into the supply chain.

-

Export Orientation: From the outset, a portion of the production should be targeted for export to regional markets, forcing the entire ecosystem to become globally competitive.

The Chromebook assembly line is an undeniable achievement. But its ultimate legacy will not be the devices it produces, but the industrial ecosystem it has the power to ignite. The ambition is clear; now the hard work of building around it must begin.

Leave a Reply